Rotating Plant Stand

tl;dr: I learned Fusion to design and make a 3D‑printed rotating plant which slowly turns a plant on a platform using a DC motor, planetary gear reductions and ball bearings; it runs ~10.5 hours per revolution and draws less than 0.1 W when powered at 5 V via a USB‑C trigger board, more below the video.

I keep a list of ideas I’ve titled “Million Dollar Ideas” and one of them was to make a plant stand which slowly rotates to turn the fern I’m barely keeping alive in my basement office past an arc of light to keep it alive a little longer.

A few years ago I got a Prusa Mini+ 3D printer and have been futzing around with printing stuff for around the house but my ideas for things quickly outgrew what I had the patience to make with Tinkercad but I was also having a hard time “getting into” a “real” CAD like Fusion.

Tinkercad has a very low barrier to entry and is free-as-in-price, you can glue together shapes into a 3d object and print them but it doesn’t have the ability to easily change your parts or the assembly of parts, dimensioning things is difficult, things like getting stuff tangent to a curve is a pain, etc. This rotating stand would definitely be beyond my patience to design in Tinkercad.

So I took a Fusion class at PCC, Fusion is great and free-as-in-price (for hobbyists) and a lot more capable. I learned a lot quickly and it was very fun. I was expecting to just learn Fusion and then design the plant stand after the class was over but the class also required a final project and this rotating plant stand was perfect:

✔ Uses a lot (most?) of the features we were taught.

✔ Is something I actually want.

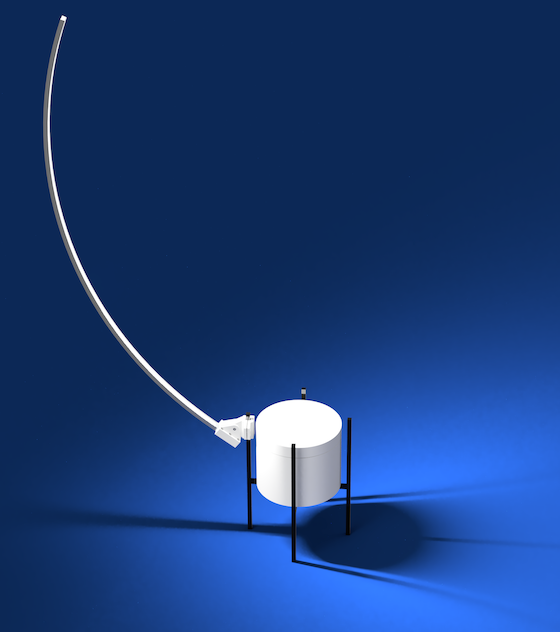

Here’s what I ended up designing:

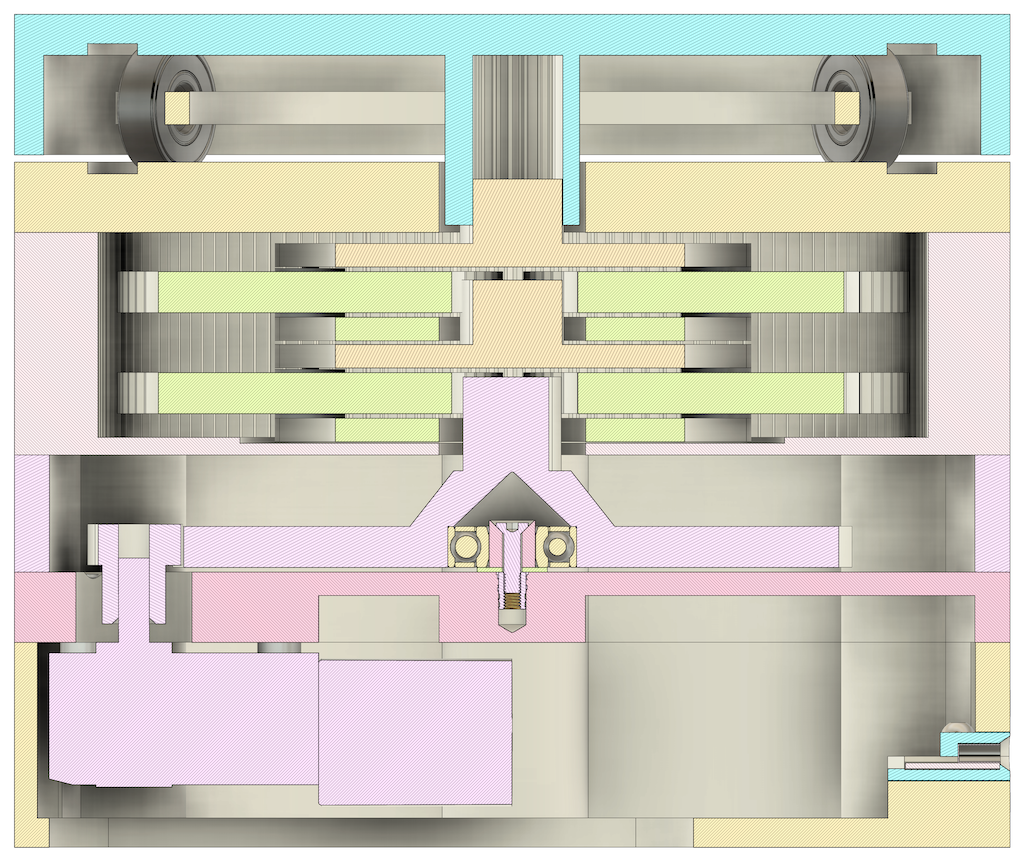

At the bottom a USB-C input provides power, drives a DC motor and gearbox which drives the plastic gear train, one reduction gear into a stacked planetary set of reduction gears. The platform on top is connected with a spline to the sun output of the top planetary gear set and revolves on a set of ball bearings like a microwave turntable does so there’s no axial load on the gear train. I used a little thin UHMW tape between the gear sets which rub to keep friction down a little. The platform will rotate 360° in about 10.5 hours.

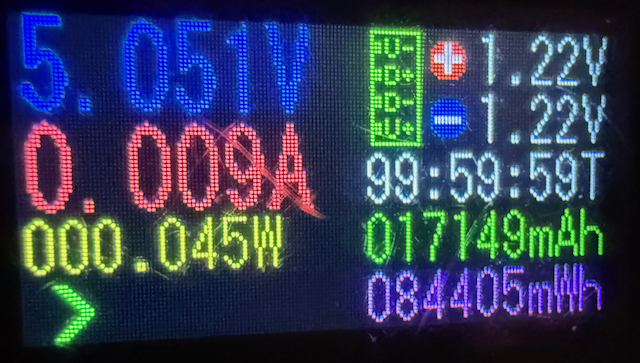

I was originally going to use an XT60 connector or a barrel jack socket for power input as I had a number of them already but when testing the platform under load it never draws more than 0.1 watt so I looked to USB and discovered the exciting world of USB-C trigger boards.

The USB-C trigger board can do the negotiation with the USB-C source and get 5/9/12/15/20v of DC power (if the source supports it), I initially tried 12v, then 9v, but the motor’s integrated gearbox was pretty noisy so I’m running it at 5v instead, it’s now quieter than the ambient noise of computers and the air filter in my basement.

Parts I couldn’t print:

- 12v 3rpm motor/gearbox from AliExpress

- USB-C trigger module

- 608 ball bearings

- UHMW tape

- M3 flat head screws

- M3 heat set inserts

- M3 12mm fender washers

Overall it was a very fun and satisfying to learn some CAD and make this project, really excited to be able to design and make more things including the arc-shaped light to illuminate the plant: